Products & Services >>

Swing Beam Presses

Why use a Swing Beam Press?

A Swing Beam Press is a highly effective method

of cutting single or multi shapes from material – single

layer or multi layer. A Swing Beam Press is a highly effective method

of cutting single or multi shapes from material – single

layer or multi layer.

The material and tool are placed under the head of the Swing Beam Press, the operator

then presses two push buttons to bring the cutting head down under force to cut

out the shape. The Swing Beam is then manually moved to one side to allow the

operator to retrieve the cut part and continue with the next cut.

These presses are very versatile and can be used by craft people working at home

with low volume production through to large production facilities with the press

working shifts 24hours per day.

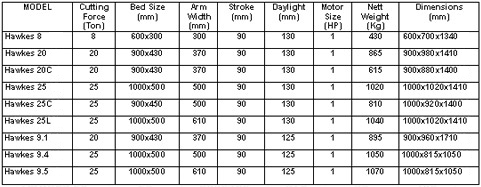

A wide choice of different models

From the smallest 8 Ton Model to the largest 25 Ton Model, Hawkes Swing Beam

Presses are adaptable to a vast range of applications. Suitable for cutting

a wide range of materials, including:

- Carpet

- Carpet & Textile Pattern Books

- Felt

- Paper & Card

- Flooring

- Sponge

- Foam

|

- Craft Products

- Cork

- Plastics

- Leather

- Rubber

- Gasket Materials

- Electronics

- Textiles

|

- Shoe Materials

- and many more.

|

Range

Hawkes Range: Automatic knife setting for any height of knife.

Hawkes ‘9’ Range: Special stroke end setting combined with extra

light swing.

Three phase or single phase power supply available.

Value for money with no hidden costs

Our Swing Beam Presses are sold ‘ready to run’: complete with hydraulic

oil, power lead, cutting board and instruction manual.

Minimum maintenance,

Maximum safety

Specifically designed for easy maintenance. Hawkes Swing Beam Presses are completely

self-lubricating with oil pressure bearings for light head movement and long

life. All presses come as standard with a self-diagnostic panel for simple

on-the-spot trouble shooting. Presses comply with the latest safety regulations.

Peace of mind with our fast back-up service

Hawkes Swing Beam Presses offer you reliability. Our team of service staff

are always available to help you with queries and advice. We are keen to

respond quickly to your needs with engineer on site support and fast spare

parts back-up.

Easy to operate

Hawkes Swing Beam Presses are very easy to operate. You can adjust the cutting

force and knife clearance quickly & easily. Very light head movement

reduces operator fatigue. With automatic knife setting any height of knife

may be used with out the operator adjusting the depth of cut setting. This

saves time and prolongs the life of your cutting boards and tooling.

Productivity

Built for maximum speed, high productivity can be achieved 24hours a day. With

minimum deflection in the cutting arm these presses are designed for accuracy

and high output.

Efficiency

Maximum force is achieved using minimum electrical power consumption – this

greatly reduces your running costs.

Robust Construction

Presses are solid cast construction for durability & long life. Built to

cut your toughest jobs. Designed to allow no overhang of the cutting plate

this ensures high accuracy cutting at all times. |

A Swing Beam Press is a highly effective method

of cutting single or multi shapes from material – single

layer or multi layer.

A Swing Beam Press is a highly effective method

of cutting single or multi shapes from material – single

layer or multi layer.